Not all steel is the same. In fact, some steels don’t get along well together, this can be the case with carbon steel and stainless steel.

What’s the difference between these two common types of steel – Cost – Availability – don’t ignore the key properties as follows:

Carbon Steel

Carbon steel and stainless steel are both iron-based metals, but carbon steel has an especially high content of carbon. This makes carbon steel notably strong, heavy, and hard. However, carbon steel is vulnerable to corrosion. That’s because it’s made of iron, and it’s easy for oxygen to corrupt iron. The result is iron oxide, or rust, which can completely eat away at carbon steel.

Stainless Steel

You might be thinking, “Wait, if both steels are iron-based, why is stainless steel resistant to corrosion?” – Stainless steel has a secret weapon: chromium. Chromium can shrug off oxygen without corroding. The addition also pushes stainless steel higher up on the nobility chart.

So when stainless steel and carbon steel are connected, and an electrolyte such as moisture is introduced, stainless steel absorbs carbon steel’s electrons. Carbon steel can deteriorate rapidly, become weak, and become the root cause of failure.

What Is Galvanic Corrosion?

Galvanic Corrosion is the reason connecting carbon and stainless steel can lead to problems. Galvanic corrosion is when one metal causes another metal to corrode and break down. For this corrosion to start, there need to be three things: an anode (one metal), a cathode (a second metal), and an electrolyte (water is a common one). Some metals are more likely to give their electrons away, and others are more eager to pull in extra electrons. That means combining these different types of metals in electrolyte-heavy environments causes one metal to hand its electrons over to the other. When a metal gives away electrons, galvanic corrosion starts, and the metal rusts.

How Does Galvanic Corrosion Happen?

When two dissimilar metals are connected to each other, the electrolyte helps move one metal’s electrons to the other metal. As the electron-generous metal loses electrons, it undergoes oxidation.

Oxidation causes the metal to rust, weaken, and disintegrate.

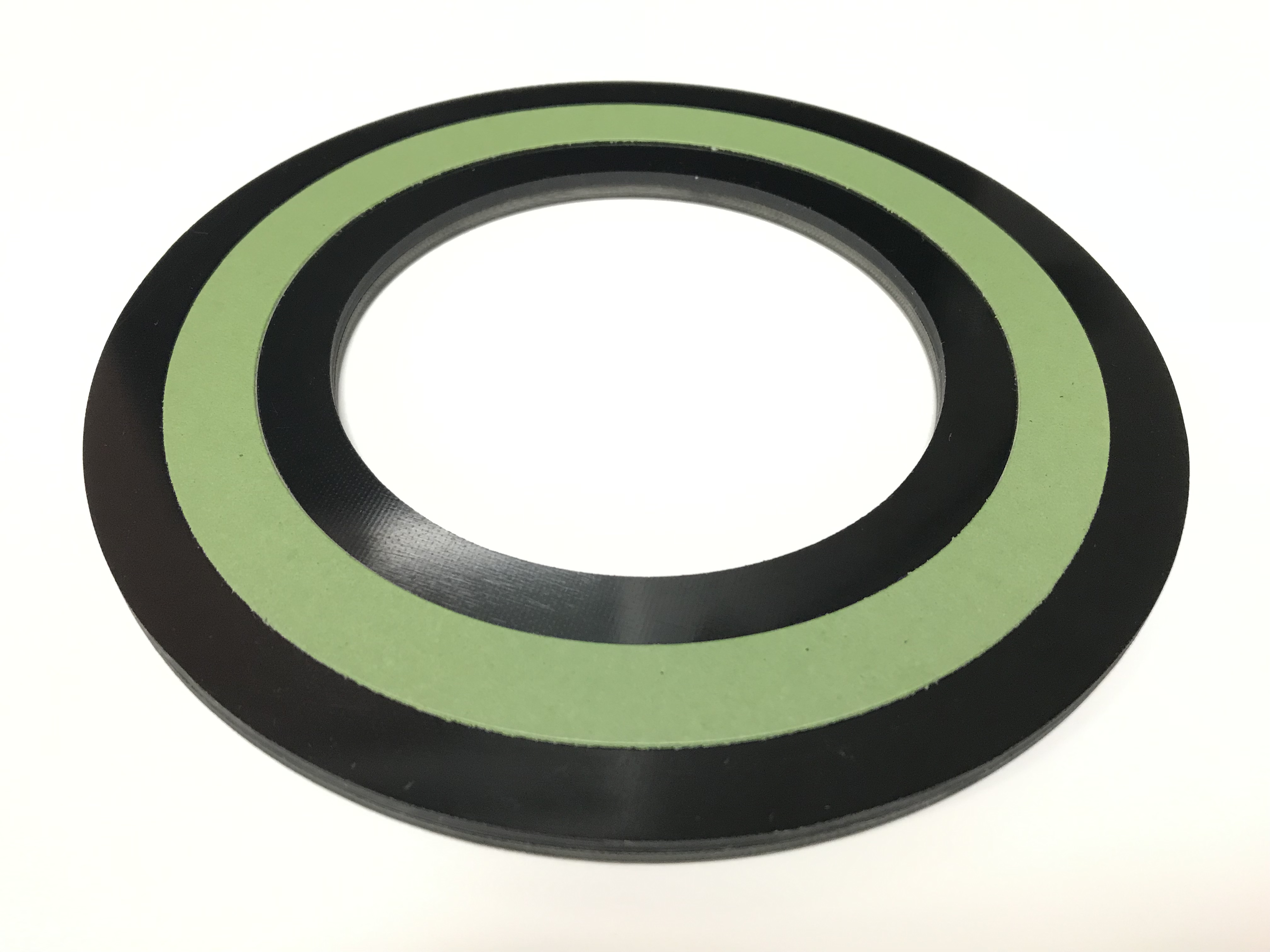

Flange insulation and electrical isolation in conjunction with cathodic protection. • To isolate flange and piping systems where dissimilar metals are present.

For further information of Flexitallic response to such industry issues please contact the Academy to review solutions including our range of ISOFLEX Isolating Kits .